Lighting as Spatial Dialogue

- Studio amorphous

- Jan 2

- 2 min read

At amorphous design lab, we believe lighting should never be an afterthought or a generic addition to a room. Instead, we view it as a spatial narrative—a primary element that defines the character, dimensionality, and emotional resonance of an environment. We approach every commission through a lens of spatial integration, ensuring that each bespoke piece is not just in a space, but fundamentally of the space.

The Power of Being Material Agnostic

Our design philosophy is rooted in a refusal to be limited by a single medium. We are material agnostic. Whether a concept calls for the warmth of hand-turned wood, the precision of CNC-milled aluminum, or the ethereal translucency of 3D-printed polymers, we let the design intent dictate the material—never the other way around. This flexibility allows us to respond authentically to the unique materiality and concept of the project at hand.

The Hybrid Advantage: Design Meets Fabrication

What sets us apart is our identity as designer-manufacturer hybrids. In an industry where vision and execution are often separated by third-party vendors, we bridge the gap. By housing both the design studio and the fabrication lab under one roof, we eliminate the "lost in translation" phase.

This hybrid model allows us to experiment with high-fidelity prototyping and custom engineering in real-time. When we propose a complex kinetic installation or a five-foot-long aerodynamic luminaire, we aren't just presenting a sketch—we are presenting a piece we have already begun to solve technically. This vertical integration ensures that the final product maintains the purity of the original design while meeting rigorous functional standards.

From Digital Innovation to Physical Mastery

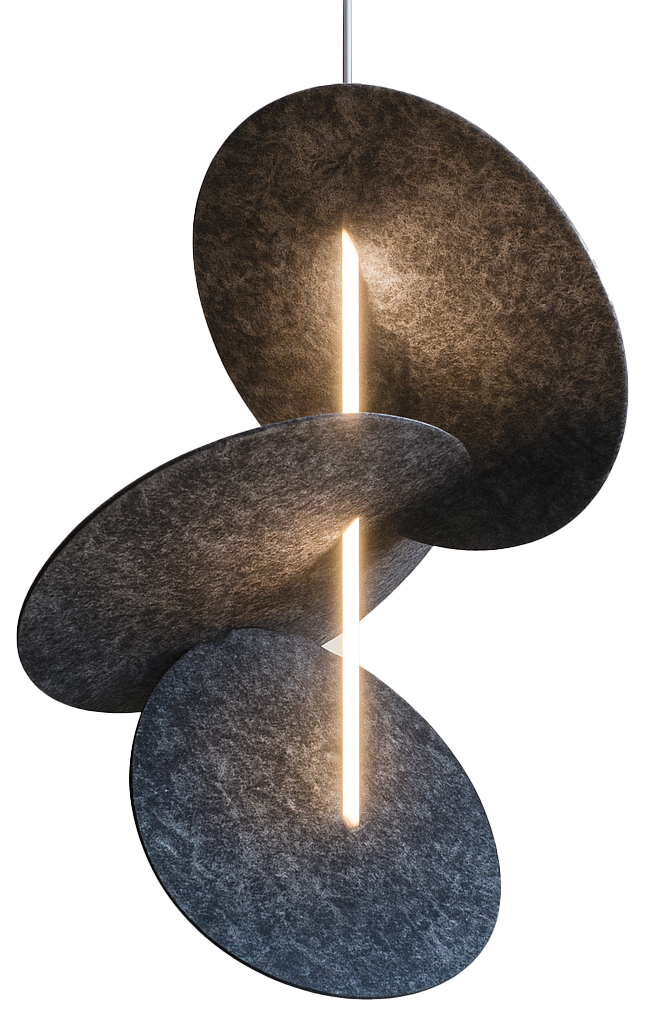

Innovation at amorphous is driven by a high-tech, high-touch workflow. We leverage large-format 3D printing to prototype complex geometries, allowing us to test light dispersion and form with surgical precision.

However, we do not allow technology to dilute the soul of the work. Our process seamlessly transitions from digital fabrication to traditional craftsmanship. We might marry a 3D-printed frame with hand-lacquered accents inspired by Channapatna traditions, or integrate acoustic PET felt into kinetic metal structures. By refusing to compromise on the method of making, we ensure that every installation provides a tactile and visual depth that mass-produced fixtures simply cannot achieve.

Comments